Abstract

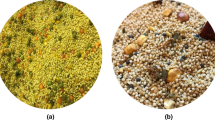

There is an increased demand among the consumers for convenient foods for various reasons. Millets such as little, proso, barnyard and ragi were explored for processing into Ready-To-Cook (RTC) millet flakes to meet the needs of modern consumers. Physico-functional and nutrient composition of RTC millet flakes were evaluated against the control (oats flakes and rice flakes). Variation in physical, functional and nutrient composition were observed among the flakes. The RTC flakes of minor millets were smaller in size and density but more fragile and crisp than the commercial oats and rice flakes. Higher flake volume (16.35 ml) and lower bulk density was recorded in little millet flakes (0.15 g/ml). Good cooking properties were recorded in all millet flakes. Lowest fat content (0.40 g/100 g) was recorded in little millet flakes whereas proso millet flakes exhibited highest crude protein (14.72 g/100) and dietary fiber (21.56 g/100 g). Among the millet flakes, RTC little millet flake was most acceptable in terms of sensory quality and also exhibited good shelf life of four months at ambient temperature of 24-31 °C. The microbial load decreased during storage period and was within permissible limits.

Similar content being viewed by others

References

Amerine MA, Pangborn RM, Roessler EB (1965) Principles of sensory evaluation of food. Academic Press, Elsevier, London

AOAC (1995) Official methods of analysis, 20th edn. Association of Official Analytical Chemists, Washington

AOAC (1996) Association of Official Analytical Chemists. Official methods of analysis, 16th edn. Gaithersburg

Asp NG, Johansson CG, Hallmer H, Siljestroem M (1983) Rapid enzymic assay of insoluble and soluble dietary fiber. J Agric Food Chem 31:476–482

Ayo JA, Oluwalana IB, Idowu MA, Ikuomola DS, Ayo VA, Umar A, Yusuf E (2011) Production and evaluation of millet-egg-soybean hull composite flour: a weaning food. American J Food Nutrition. doi:10.5251/ajfn.2011.1.1.7.13

Bureau of Indian Standards (2006) Indian Standard processed-cereal based complementary foods-specification

Chakraborty SK, Singh DS, Chakraborty S (2009) Extrusion: a novel technology for manufacture of nutritious snack foods. J Beverage Food World 42:23–26

Deshpande HW, Poshadri A (2011) Physical and sensory characteristics of extruded snacks prepared from foxtail millet based composite flours. Int Food Res J 18:751–756

Gopalan C, Ramasastri BV, Balasubramanian SC (2004) Nutritive value of Indian Foods. National Institute of Nutrition, (ICMR), Hyderabad

Graham, R (2002) A proposal for IRRI to establish a grain quality and nutrition research center, IRRI Discussion Paper Series, 44, pp15

Huber GR (1991) Carbohydrates in extrusion processing. Food Technol 45:160–168

ICMSF (1996) Micro-organisms in foods 5. Microbiological specifications of food pathogens. International Commission on Microbiological Specifications for Foods (ICMSF). London: Blackie Academic and Professional

Ilo S, Berghofer E (1999) Kinetics of color changes during extrusion cooking of maize grits. J Food Eng 39(3):73–80

Itagi, S (2003) Development and evaluation of millet based composite food for diabetes. Ph.D. Thesis, Univ. Agric Sci. Dharwad (Karnataka)

Kotagi K (2011) Little millet (panicummiliare) flakes: development, value addiction, quality evaluation, consumer acceptability and commercialisation. Thesis, Univ Agric Sci Dharwad (Karnataka), Ph. D

Kumari K, Thayumanavan (1997) Comparative study of resistant starch from minor millets on intestinal responses, blood glucose, serum cholesterol and triglycerides in rats. J Food Sci Agric 75:296–302

Lue S, Hsieh F, Huff HE (1991) Extrusion cooking corn meal and sugar beet fiber: effects on expansion properties, starch gelatinization, and dietary fiber content. Cereal Chem 68:227–229

Mishra BK, Gupta RK (1995) Protocol for evaluation of wheat quality. Technical Bulletin No. 3, Directorate of Wheat Research, Karnal, India

Nawabueze T (2006) Water/oil absorption and solubility indices of extruded African bread fruit blends. J Food Technol 4(1):64–69

Patil KB, Chimmad BV, Itagi S (2014) Glycemic index and quality evaluation of little millet (panicum miliare) flakes with enhanced shelf life. J Food Sci Technol. doi:10.1007/s13197-014-1663-5

Ravindran (1991) Studies on millets: proximate composition mineral composition and phytate and oxalate contents. Food Chem 39:99–107

Rooney LW, Pflugfelder RL (1986) Factors affecting starch digestibility with special emphasis on sorghum and corn. J Animal Sci 63:1607–1623

Roopa S, Premavalli KS (2008) Effect of processing on starch fractions in different varieties of finger millet. Food Chem 106:875–882

Sailaja YS (1992) Popping and flaking quality of sorghum cultivars in relation to physicochemical characteristics and in vitro starch and protein digestibility. Andhra Pradesh Agric Univ, Ph. D Thesis

Samahay ESK, Hady EAA, Habiba RA, Moussa-Ayoub TE (2007) Some functional, chemical and sensory characteristics of cactus pear rice based extrudates. J Prof Assoc Cactus Dev 9:136–147

Sareepuang K, Siriamornpun S, Wiset L, Meeso N (2008) Effect of soaking temperature on physical, chemical and cooking properties of parboiled fragrant rice. World J Agric Sci 4(4):409–415

Seth D, Rajamanickam G (2012) Development of extruded snacks using soy, sorghum, millet and rice blend – a response surface methodology approach. Int J Food Sci Technol 1-6

Ugare R, Chimmad B, Naik R, Bharati P, Itagi S (2014) Glycemic index and significance of barnyard millet (echinochloa frumentacae) in type II diabetics. J Food Sci Technol 51(2):392–395

Ui J, Kondo K, Sawada T, Hara-Kudo Y (2009) Survival of foodborne pathogens in grain products and the effect of catechins. J Food Hygiene Society Japan 50(3):126–130

Yenagi NB, Vanita N, Mannuramath M, Josna B (2013) Evaluation and modification of existing emery flour mill for improving milling efficiency of little millet (panicum sumatrense)proceedings of international workshop on promoting small millets for improved rural economy and food security, Feb 8–9, 2013. Dharwad, UAS

Author information

Authors and Affiliations

Corresponding author

Additional information

Research highlights

• Minor millets are nutritionally superior to major cereals and possess therapeutic benefits for the modern life style. Utilization of millet is limited owing to drudgery associated with its processing. There is a need to provide millet based convenient foods to the modern consumers to reap health benefits associated with millets.

• The research highlights the findings of development of consumer friendly Ready-To-Cook (RTC) millet flakes based on little millet (Panicum miliare), proso millet (Panicum miliaceum), barnyard millet (Echinochloa frumentacea), finger millet (Elusine coracana) without any added chemicals or preservatives.

• The nutritional composition and functional properties of RTC millet flakes were good indicating better utilization than their respective grains. The RTC flakes provide convenience in terms of utilization, storage and acceptability.

• RTC millet flakes exhibited excellent sensory profile in the form of traditional food i.e. avalakki/poha. Among the different flakes, the little millet flakes were highly accepted by the consumers.

• The RTC little millet flakes exhibited good shelf life of four months at ambient storage condition (24-31 °C and relative humidity of 42–82 and 61–98 %). The flakes possessed good sensory quality and were microbiologically safe.

Rights and permissions

About this article

Cite this article

Takhellambam, R.D., Chimmad, B.V. & Prkasam, J.N. Ready-to-cook millet flakes based on minor millets for modern consumer. J Food Sci Technol 53, 1312–1318 (2016). https://doi.org/10.1007/s13197-015-2072-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-2072-0